NDJ-1 Rotary Viscometer

LVTV-2C Viscometer

NDJ-4 Rotary Viscometer

NDJ-4 rotary viscometer is an instrument used for determining the liquid viscose capacity and the dynamic viscosity.

Operation Manual

For

NDJ-4 Rotary Viscometer

MADE IN CHINA

hank you for using NDJ-4 Rotary Viscometer.NDJ-4 is easy to use,in order to install and operate accurately,and make full use of product features,we suggest you to read the manual before using.

·The company possesses the final interpretation power.

·The company reserves the power of amending technical rules without prior notice.

·The company reserves the power to amend the manual without further notice.

·May not be translated into other languages,reproduction prohibited without written permission.

General

NDJ-4 rotary viscometer is an instrument used for determining the liquid viscose capacity and the dynamic viscosity.NDJ-4 has been widely used to determine and measure the liquid viscosity in many applications such as grease,painting,plastic,pharmacy and adhesives.It is a precision instrument to monitor and control the stable quality of products in the manufacturing.

Main technical data

1)Measurement range:10-2×106 mPa·s

2)Rotor specification:1,2,3,4,four kind rotor

3)Rotor velocity:L(slow rate)

0.3rpm,0.6rpm,1.5rpm and 3rpm

H(high rate)

6 rpm,12 rpm,30 rpm and 60 rpm

4)Measurement error:±5%(Newton Liquid)

5)Power supply:Voltage—220±22V,Frequency—50 Hz±0.5Hz

5)Dimensions:300 mm×300 mm×450 mm

6)Net weight:2 Kg(not included base)

Installation

1.Take out the bracket,package and hoisting column from the packaging.

2.Screw the lifting column to the base collet after the fixed trestle,and make the surface of tooth profile facing to the rear of the base.Tight hex nut by wrench to avoid loosen.

3.Check the flexibility and self-locking performance of the lifting collet,adjust the clamping bolt to make the instrument moving up and down,and to protect it drop down from column.If too tight and too loose,use screwdriver to adjust the collet screw.

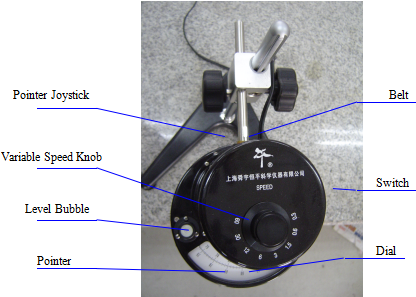

4.Take out viscometer form package and mount it on the lifting collet,tight it by handle setscrew to avoid loosen(as level as possible),take away the rubber band on the pointer joystick,take away the yellow protection cycle below the viscometer,then take out the protection bracket,and screw it into the viscometer.

5.Adjust the adjustment screw and put the rotor into the liquid to be measured till the level mark on the rotor reach the liquid surface.

6.Connect the power.

Operation

1.Prepare the liquid to be measured and put it into a glass beaker or a right angle container with the diameter not smaller than 70 mm,take care of the liquid temperature.

2.Mount the protection bracket on instrument,turning left for mounting,turning right for removing.

3.Screw the selected rotor into connecting rod,turning left for mounting,turning right for removing.Adjust the lifting screw and put the rotor into the liquid to be measured till the level mark on the rotor reach the liquid surface.Connect power supply,turn on the equipment,screw the speed knob,select velocity,relax pointer joystick,reading data can be displayed(about 20~30 seconds)when the pointer becomes stable.Reading data can be displayed(about 20~30 seconds)when the pointer becomes stable.Press the pointer joystick after pointer becoming stable,cut power supply,then get the reading data.If the pointer isn’t in reading window after motor stop,you can press pointer joystick unceasingly,open or close the motor time after time,after practice,you can operate it familiarly.

(Notice:1.Shall not apply excessive force.

2.Do not use pointer joystick when rotation is slow.)

This time,could get measuring date.If the pointer is not in the reading window,could press the pointer,then opened and closed the motor repeatedly.

4.When the reading data is too high or too low,the rotor or the rate can be changed,make sure the reading data is between 30 and 90.

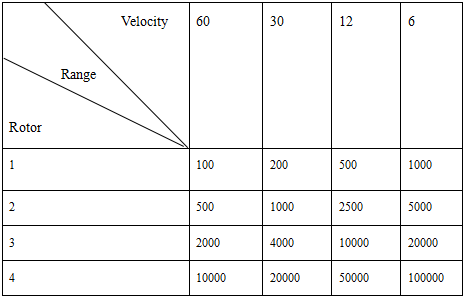

5.Choice of range,coefficient,rotor and rate:

5.1 Estimate approximately the viscose range,then select the rotor and the velocity according to the range table:

For example,the viscosity of liquid is about 3000 mPa·s the settings should be as following:

rotor 2#with velocity of 6 rpm,

rotor 3#with velocity 0f 30 rpm

5.2 If the viscosity of liquid can not be estimated,you should set a high viscosity value,the rotor volume should be selected from smaller to larger with their rate from slower to quicker.In general,high viscosity should use smaller rotor with slower velocity,lower viscosity use lager rotor with faster velocity.

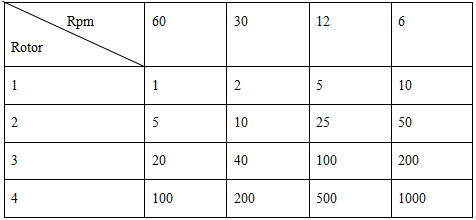

5.3 Coefficient:the reading must be multiplied the specific coefficient in the coefficient table in order to get the dynamic viscosity.

5.4 Amendment of frequency error:when the power frequency is inaccurate,you can amendment it according to the formula below:

Actual viscosity=instruction viscosity*nominal frequency/actual frequency

Conversion dynamic viscosity between kinematic viscosity

μ=v*ρ

μ=sample kinematic viscosity(mPas)

v=sample dynamic viscosity(mm2/s)

ρ=the sample density in the same temple of measuring kinematic ciscosity

5.5 Unit conversion

1 cP=1 mPa.s

100 cP=1 P

1000 mPa.s=1 Pa.s

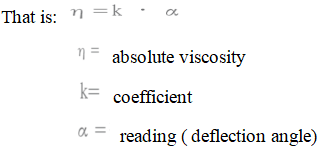

5.6

5.7 Coefficient table:

Precaution

1.This instrument is limited to the room temperatures

2.This instrument should be used under the designed voltage and frequency and their allowable error ranges,or incorrect results could be resulted.

3.Using the bracket fix the instrument in order to determine accurately.Handheld operation:keep the instrument stable and level.

4.Care should be taken for mounting or removing rotors,slightly and lift the connecting screw bolt to avoid a transverse force acting on rotor to cause it bending.

5.The instrument mounted with rotor should not be revolved.

6.Don’t run the motor when the pointer joystick is not pressed.

7.Keep cleaned on screws and connecting points between rotor and connecting bolt rod,or a unstable rotation could be caused in the real measurement.

8.Use hand to hold the instrument when lifting up or moving down to avoid dropping it.

9.After completing measurement each time,the rotor should be fully cleaned(rotor should be removed from instrument for cleaning),then place it on the protection bracket.

10.Unauthorized removing or replacing the instrument part,and applying lubricates are not allowable.

11.When moving or shipping instrument,put on the yellow caver cap and lift the connecting bolt rod and screw the bolt on the cap tightly.

12.Suspension,emulsion or polymer and other high viscosity liquids are non-Newton liquids,their viscosity will change with shear velocity and time,it is normal for their measured inconsistent results under the selected rotor and velocity and time,and it is not resulted from the instrument problems(in general,the rotor and velocity and time should be specified for non-Newton liquids).

13.The cautions should be taken for followings to obtain a good measuring reault:

(1)Accurately control the temperature of liquid to be measured;

(2)Make temperature of rotor and protection bracket same as liquid;

(3)Ensure the liquid homogeneity and without bubbles;

(4)Put the rotor located on the center of the liquid container in real measurement;

(5)Remove bubbles adhered on the rotor when put it into liquid;

(6)When change the rotor or rate,keep between 30~90 as possible.

(7)Use rotor protection bracket for measurement;

(8)Ensure rotor and connecting screw rod cleaned;

(9)Amend according to the amending formula when power frequency is not exact.

(10)When pointer is stable,reading with the same angle of view.

(11)Adjust level bubble exactly,move the instrument slowly,keep the instrument stable.

(12)Strictly follow the operation instruction for measurement.